Plastic Extrusion

-

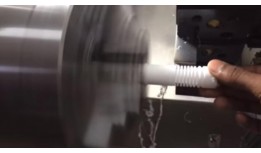

PTFE Bellows Forming Machine

PTFE bellows are used, for example, as compensating elements between engineered parts. By specifically using different fold geometries, any combination of properties can be achieved as required—for example, high flexibility or compressive strength. PTFE Bellows Properties Almost universal chemic...Read more -

Extrusion of Plastics – Working Principle and Process Parameters

Extrusion is a high volume manufacturing process. The plastic material is melted with the application of heat and extruded through die into a desired shape. A cylindrical rotating screw is placed inside the barrel which forces out molten plastic material through a die. The extruded material takes...Read more -

Polymer Extrusion & Injection Molding Process Comparison

Extrusion is widely used in various industries.The screw in the extruder rotates and develops sufficient pressure to force material to go through a die and produce products with desired geometry. Injection molding is the most commonly used manufacturing process for the fabrication of plasti...Read more -

Plastics Processing and Manufacturing,Process of Plastic Extrusion

Plastic extrusion is a process where plastic is melted and formed into a continuous form. This process is used for producing things such as pipe, fencing, tubing, wire insulation, window frames, and railing… Plastics Processing and Manufacturing Plastics are polymers with high molecular wei...Read more -

Blow Molding & Compression Molding Process Comparison

Blow molding ( BrE moulding ) is a manufacturing process by which hollow plastic parts are formed: It is also used for forming glass bottles. In general, there are three main types of blow molding: extrusion blow molding, injection blow molding, and injection stretch blow molding.Compression mold...Read more -

Plastic PTFE Corrugated Pipe Extrusion Machine

All our components and automation systems are consistently engineered to maximize savings on materials, energy and costs,without compromising on product quality. We are your expert partner for any type of pipe extrusion line. Suko has everything you need for producing plastic PTFE lined pipes fro...Read more